It is without doubt one of the important technologies that's driving this integration. IIoT capabilities are now being included to Haas machines to allow them to converse with other devices and systems within the manufacturing unit.

After you're wanting to go, the following stage will be to identify your use cases. They're the particular difficulties or opportunities in which you think AI can assist.Remember, AI is not a silver bullet which can fix all your problems. It is a Instrument which is good at certain things, like obtaining designs in knowledge, making predictions, and optimizing procedures.

Leading Equipment is usually a proud American organization celebrating a lot more than thirty decades of customer satisfaction. We're devoted to escalating and contributing to America’s work force by maintaining our headquarters and employees while in the United States of The usa.

Floor roughness is regarded as One of the more specified customer demands in machining processes. For efficient use of machine tools, variety of machining course of action and determination of exceptional cutting parameters (velocity, feed and depth of Reduce) are needed. Hence, it is necessary to seek out a suitable way to choose and to discover optimal machining course of action and cutting parameters for any specified surface roughness values. In this particular perform, machining process was completed on AISI 1040 steel in dry cutting issue inside a lathe, milling and grinding machines and floor roughness was calculated. Forty five experiments are already done making use of different speed, feed, and depth of Reduce to be able to locate the area roughness parameters. This information has long been divided into two sets on the random foundation; 36 training information established and 9 tests facts established.

Over time, AI will renovate the machining industry, boosting productivity and escalating profitability for numerous organizations. AI’s affect is profound and expansive. Although adopting technology rising will come with challenges, the benefits are definitely worth the so-referred to as “teething phase.”

AI’s role in optimizing production scheduling is essential for maximizing efficiency. A 2024 examine by the International Journal of Production Economics uncovered that AI-driven scheduling systems can make improvements to production efficiency by up to twenty%.

The technological storage or access is strictly essential for the legit objective of enabling using a particular service explicitly asked for by the subscriber or user, or for the sole function of finishing up the transmission of the conversation in excess of an Digital communications network. Tastes Choices

Predicting Resource dress in though machining is often a hard element. Traditional strategies to use system features that influence Device wear are available, having said that, some parameters are unique for the machining procedure, and present prediction versions are unsuccessful. The present work discusses a system supervision system that employs machine Understanding (logistic regression) to anticipate Software dress in. An software for your prediction of Resource put on even though milling is decided on as being a case review to demonstrate the methodology. Another dataset will probably be designed by running the milling Procedure with the end mill cutter less than 3 distinctive problems, namely one.

CNC machines, significantly CNC mills and CNC lathes, are essential for exact and efficient manufacturing. CNC mills, including vertical and horizontal milling machines, are perfect for specific cutting and shaping of products, presenting capabilities like intricate contouring and surface area finishes. CNC lathes excel in turning functions, offering high-pace rotation for machining cylindrical parts with precision.

The integration of AI into CNC machining is more than a craze; it’s a paradigm shift. Individuals that embrace this revolution will lead how in innovation, efficiency, and top quality, environment new standards for that industry throughout the world.

Cost-performance: AI’s predictive capabilities allow for for proactive servicing, resulting in cost price savings by guaranteeing timely servicing.

Which is what precisely artificial intelligence more info can offer. When a machine is driven by info and operators get true-time streams of data suggestions, predictive measures could be taken.

Milling CNC machines can be found in a big selection of sizes and kinds and operate on several axes. The 2 key forms of CNC mills are horizontal and vertical referring for the orientation from the cutting tool.

CNC machining and AI enhance one another beautifully. AI’s ability to assess broad quantities of facts and understand from it makes AI a really perfect companion for CNC machining. When used appropriately, AI enhances production capacity, boosts machine productivity, and optimizes producing processes.

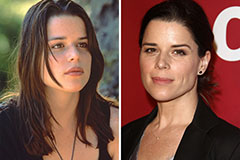

Neve Campbell Then & Now!

Neve Campbell Then & Now! Robert Downey Jr. Then & Now!

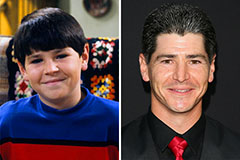

Robert Downey Jr. Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!